to clean and decarbonise the air

ClimaHtech Green Flight offers SAF production (e-SAF and Bio-SAF) via renewable electricity and sustainable biomass in a modular, decentralised, and scalable system.

E-FUEL GEN TECHNOLOGY

ClimaHtech’s E-FUEL GEN technology is a breakthrough innovation in the production of Sustainable Aviation Fuel (SAF). Developed by CATAGEN, this electrically driven, modular system uses renewable hydrogen and sustainable carbon dioxide to produce e-SAF, and when paired with BIOHGEN, also enables the production of bio-SAF.

Unlike traditional SAF pathways reliant on complex infrastructure or scarce feedstocks, E-FUEL GEN is designed to be decentralised, scalable, built for rapid deployment and engineered to align with the ASTM FT-SPK pathway for SAF certification.

Ultra-low carbon intensity SAF will be produced via electrification to Fischer-Tropsch (unlike gasification to FT which requires sacrificial fuels to heat the process).

Decentralised SAF production

- Colocation with renewables

- Local fuel security – SAF Production anywhere there is renewable energy.

- E-reactor reduces amount of electricity needed for production – can integrate into existing renewable capacity. 1.8 MW of electricity produces 1 million litres of fuel.

Electrically driven reactor

-

Leverages renewable electricity: Eliminates the need to divert feedstock for energy, preserving resources.

-

High Operational Efficiency: Delivers optimal energy-to-fuel conversion rates, ensuring cost-effective and sustainable fuel production.

-

Low Carbon Intensity: Achieves a minimised carbon intensity score.

Accelerated Deployment Timeline

- Our system’s modularity allows for scaling in line with demand and power availability, facilitating rapid expansion.

- Utilises off-the-shelf components, streamlining the manufacturing process and reducing lead times.

- Skid-mounted units require minimal site adaptation, enabling deployment across various locations without extensive groundwork.

- Capable of producing fuel within three years from project initiation, significantly faster than conventional plants.

Lower capital investment

- Lower capital investment for FID

WHY DECENTRALISED PRODUCTION?

- Speed to deployment through prefabricated, quality-controlled modules

- Co-location with renewables to use constrained or curtailed power

- Lower CapEx than traditional centralised SAF projects

- Resilience to intermittency via our electrically-driven reactor

- Stronger regional benefits, including energy independence and local economic retention

This model is already attracting interest from airlines, airports, energy developers and fuel suppliers — who recognise decentralisation as essential to meeting SAF mandates.

In partnership with Ryanair and Shell Aviation Ireland Limited (MJV)

CATAGEN announced a new strategic partnership with Ryanair and Shell Aviation Ireland Limited (MJV) for off-take agreements of sustainable aviation fuel (SAF) production and use.

FOUNDED ON CATAGEN'S E-REACTOR TECHNOLOGY

At the centre of our system is the OMEGA E-Reactor, originally engineered by CATAGEN for green emissions testing and adapted to enable high-efficiency thermochemical conversion for SAF. Electrification allows precise heating, renewable-ready operation, and very low carbon intensity fuel pathways.

Electrifying SAF production

Powered by CATAGEN’s proven E-reactor technology – with over 200,000 hours of operational run time.

The e-reactor technology electrifies common chemical reactions using renewable energy.

Its resilience to power intermittency makes it ideal for wind and solar integration as it can tolerate input power fluctuations.

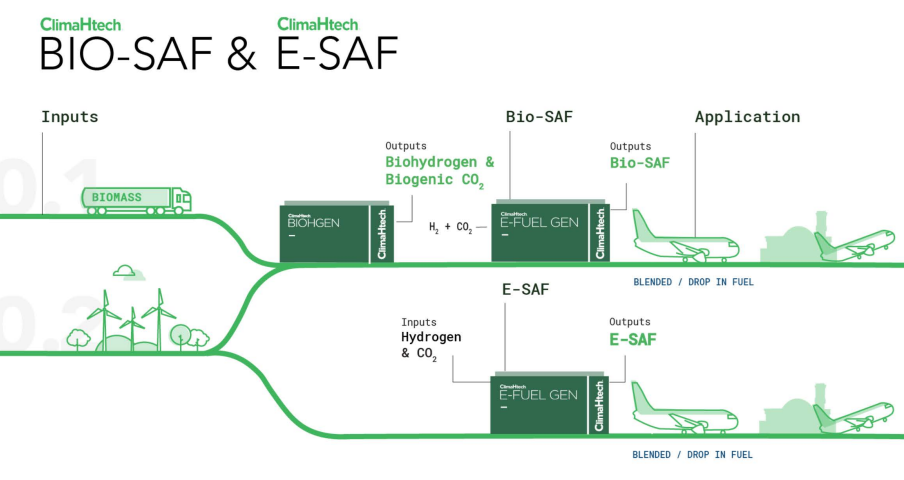

SAF PATHWAYS

The Bio-SAF pathway combines ClimaHtech BIOHGEN and E-FUEL GEN to produce gHreen bio-SAF. BIOHGEN produces biohydrogen and biogenic carbon dioxide, providing both of the building blocks for SAF in one step. This pathway uses less water and renewable energy to generate hydrogen compared to other technologies such as electrolysis. CATAGEN’s bio-SAF pathway is non-HEFA (Hydroprocessed Esters and Fatty Acids).

The e-SAF pathway combines ClimaHtech HGEN, CAPTURE and E-FUEL GEN to produce gHreen e-SAF from hydrogen and carbon dioxide. Other suitable sources of hydrogen and carbon dioxide can also be used.

ASTM PATHWAYS

CATAGEN was the first company to submit a SAF sample to the EU SAF Clearing House in 2024. Currently engaged with the Clearing House to move through fast-track certification on the ASTM D7566 Annex 1 approved pathway. By aligning with existing approved pathways, our SAF enables aviation to be decarbonised as quickly as possible.

FIRST-OF-A-KIND PROJECT

CATAGEN is preparing to deploy its ClimaHtech Green Flight solution through a First-of-a-Kind (FOAK) project. Set for completion by 2029, this project will produce decentralised SAF near primary renewable energy sources, enabled by the OMEGA e-reactor. The FOAK will serve as a critical validation of the technology’s readiness, efficiency, and compatibility with real-world energy systems.

SAF INSIGHT

Jet Fuel, Redefined: ClimaHtech’s Decentralised Path to Cleaner Skies

Sustainable Aviation Fuel (SAF) is the only scalable solution for decarbonising today’s aircraft fleets—but the existing fuel supply chain isn’t built for the speed or scale the climate demands.

Traditional, centralised refineries are slow to build and infrastructure-heavy. To meet 2030 targets, we need a faster, smarter approach.

ClimaHtech Green Flight offers a modular, decentralised solution using CATAGEN’s OMEGA e-reactor—designed to produce SAF close to renewable energy sources, capturing electricity that would otherwise be lost and turning it into climate-critical fuel.

Redefining SAF

We’re bringing together those who share a vision for aviation beyond fossil fuels.

Sign up for updates on our latest projects, insights and content as we advance the production of Sustainable Aviation Fuel (SAF).

ClimaHtech Green Flight builds on nearly two decades of CATAGEN’s innovation in thermochemical reactor design, green emissions testing and net-zero technologies. The ClimaHtech portfolio is enabled by CATAGEN’s engineering heritage, technology and purpose:

to clean and decarbonise the air

LATEST NEWS